Understanding the Impact of ERP on Freight & Tariff Management in the USA

April 15, 2025

Why UK-Based Manufacturers Need ERP for Tariff & Trade Compliance

May 13, 2025How Singaporean Manufacturing Firms Use ERP to Optimize Smart Factory Initiatives

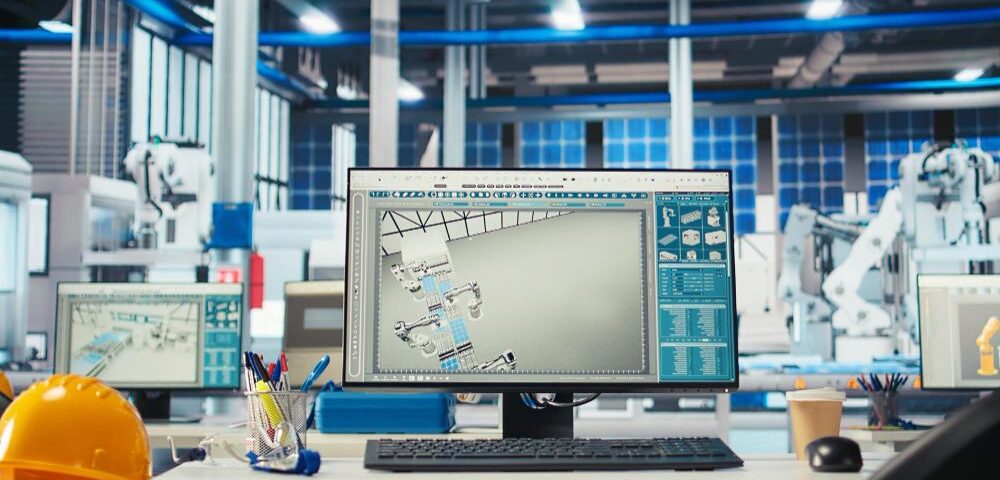

Smart manufacturing has been embraced by Singapore due to the advancement and innovation it entails. With the changing face of manufacturing through Industry 4.0 all over the world, local manufacturers are already gearing up to adopt advanced levels of ERP. The Manufacturing ERP software runs into seamless digital backbone through integration of multiple operational areas. Moreover, it gives real-time data and understanding to boost efficiency, agility, and innovation throughout advanced manufacturing environment.The Rise of Smart Factories in Singapore

A major transformation is being worked out in Singapore's manufacturing sector, which is an important pillar of the economy. Smart factories are increasingly attracting investments from many companies, mainly due to initiatives such as SIRI-the Smart Industry Readiness Index and an emphasis on high-value manufacturing. The technologies combine advancements in areas such as Industrial Internet of Things (IIoT), artificial intelligence (AI), machine learning (ML), robotics and automation, and advanced analytic technologies to create interconnected, data-driven manufacturing facilities able to dynamically respond to new market demands and optimize every stage of production process. The success of these smart factory programs is dependent on the effective management and utilization of the large quantities of data produced by these technologies, and this is where ERP becomes critical in manufacturing.The Crucial Role of ERP in Smart Manufacturing

ERP for Smart Manufacturing assumes greater importance beyond accounting and inventory management. Modern Manufacturing ERP software serves as the central nervous system of a smart factory, integrating relevant data from many smart technologies and operational processes. Thus, it acts as one platform providing real-time visibility for the entire value chain, from raw material procurement to the delivery of the final product.Here is how Singapore ERP system empowers smart factory initiatives:

- Real-time Data Integration and Visibility: Almost every smart factory is constantly flooded with ample amounts of continuous data generated by a plethora of interconnected devices and systems. This data is integrated into ERP software Singapore, which can act as the backbone for collecting and integrating data acquired from different smart devices, sensors, and machines. Thus manufacturers can have a complete real-time view of their operations for identifying bottlenecks, tracking performance, and taking proactive and informed decisions.

- Enhanced Planning and Scheduling: More accurately and effectively planned and scheduled production is now allowed by ERP Singapore as real-time access to information about inventory levels, production capacity, and customer demand is possible. AI-powered ERP modules can process both past data and real conditions to produce better production schedules and resource allocation, as well as shorter lead times. This is extremely important in a smart factory whose primary business activity is how responsive it can be under dynamically changing demands.

- Improved Quality Control: The integration of quality management systems with ERP enables real-time product quality monitoring throughout the particular manufacturing process. Sensor data and inspection system data can be automatically fed into the ERP system, which generates alerts for deviations and allows for immediate corrective actions. This aspect contributes to improved product quality and lesser waste, which is one of the major goals of smart manufacturing.

- Optimized Inventory Management: Smart factories come with very complicated supply chains and diverse components for production. The best ERP software in Singapore is made up with the most advanced inventory management capabilities, as they give real-time updates on inventory levels, and stock optimization based on demand forecasts as well as production schedules.

- Seamless Supply Chain Collaboration: In Singapore, an ERP application provides seamless communication and collaboration throughout the whole supply chain. Integrating with supplier systems and logistics providers via ERP, enables the sharing of real-time information, improved forecasting and better coordination. This is critical to optimizing material flow and timely delivery in a smart manufacturing environment.

- Data-Driven Decision Making: The huge amount of data generated in a smart factory cannot be considered useful unless it is analyzable data and an insight is possible to derive from it. But enterprise resource planning Singapore packages itself with advanced analytics and reporting functionalities that enable manufacturers to analyze trends, forecast future outcomes and make data-driven decisions to optimize their operations. For instance, production data analysis can be used in revealing areas for process improvement or identifying potential risks.

- Enhanced Automation and Robotics Integration: Application of modern ERP systems involves integration with automated machines and robotic systems operating in a factory. This integration allows seamless data flow from the ERP to the automated machine systems for much better control and monitoring of automated processes. For example, a production order generated at the ERP could be directly executed by the robots in the shop.

Selecting the Right ERP Software in Singapore

For Singaporean manufacturing firms starting on smart factory initiatives, choosing the right ERP software is critical. Several factors need to be considered:- Industry Specific Functionality: It is imperative that the ERP system is designed with the manufacturing industry and the sub-sector in mind.

- Scalability and Flexibility: The system should be able to scale as the company grows and adapt to evolving technological advancements in smart manufacturing.

- Integration Capabilities: Smooth integration with existing and future smart factory technologies-the IIoT platforms, AI/ML tools, and automation systems is thus crucial.

- Real-time Data Processing: An ERP system should be able to capture and process large volumes of real-time data produced by smart factory devices.

- Analytics and Reporting: Analysis and reporting are fundamental, as they empower organizations to derive insights from their data and drive decisions powered by those insights.

- Mobile Accessibility: Access to real-time data and core functionalities on mobile devices is becoming increasingly important in a connected manufacturing environment.

- Vendor Support and Expertise: The selection of a good ERP vendor that has experience with the Singapore manufacturing domain and is capable with smart factory technologies is the key to successful implementation and ongoing support.

How Coserve help you for ERP integration for Manufacturing industry in Singapore

As an Infor partner, Coserve Solutions utilizes its expertise in Infor technology for seamless integration of Infor ERP systems for Manufacturing industry, erp software for manufacturing industry. Services provided include custom integration development, which allows for continual data flow and process synchronization between the ERP and other enterprise applications. This integrated environment increases efficiencies and provides a 360 view of the overall business operations.This article explores the critical role ERP plays in revolutionizing these operations across the Singapore